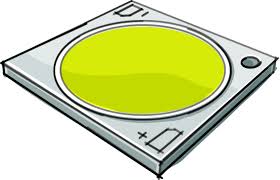

COB

(known as Chip-on-Board) is semi-conductor assembly technology where micro-chip

also known as die is electrically interconnected instead of using traditional

assembly process or individual IC packaging on the final product board. The

general term meaning of this technology is direct chip attachment also

refereeing to DCA. In DCA many kinds are available as substrate in form of

ceramic glass or ceramic substrate which has substances of excellent dielectric

and thermal property. It is also available in form of flex substrate, which

exhibits bendable ability. Other names are known as COG (chip-on-glass) or COF

(chip-on-flex).

COB

process consists of three main categories to perform when manufacturing the

Chip-on-Board. The first process is 'die mount or die attach', the second is

'wire bonding' and lastly 'the encapsulation of die wires'.

In

many COB assembly technology, FCOB(flip-chip-on-board) have chips facing

downward on the board and does not require wire bonding which employs chip

which the bond pads are pop up and it connects directly to pads on the board.

It is necessary to underfill flip-chip on active surface to protect bumps from

chemical and thermo-mechanical damage.

In

context of COB manufacturing process, 1) 'die attach' consists of applying die

attach holding to board or substrate mounting chip or die over die attach

materials. 2) For wire bonding, thermosonic (Au or Cu) ball bending and

ultrasonic (Al) wedge bending are used to connect wires between die and

substrate. Last part the encapsulation is done dispensing chemical liquid

(usually epoxy) over die and wires. Die and bond wires are encapsulated to

protect chemical and mechanical damage.

The advantages of COB include:

Better performance due to deceased interconnection between length and resistance.

And better protection against reverse engineering;

Reduced space and cost;

Shorter time to the market.

Higher reliability with better heat dispatch and small number of solder joint.

Better performance due to deceased interconnection between length and resistance.

And better protection against reverse engineering;

Reduced space and cost;

Shorter time to the market.

Higher reliability with better heat dispatch and small number of solder joint.

Applications

LED Backlight for LCD TV

LED Front light for E-Book

Agriculture & Horticulture Lighting

Street & Parking Lot Lighting

Invention

Reflective Pocket in PCB for LED Die Attachment (COB)

Patent pending

Advantages

Improved output efficiency of LED lighting

Avoid photonic absorption and scattering over the pocket wall

LED Backlight for LCD TV

LED Front light for E-Book

Agriculture & Horticulture Lighting

Street & Parking Lot Lighting

Invention

Reflective Pocket in PCB for LED Die Attachment (COB)

Patent pending

Advantages

Improved output efficiency of LED lighting

Avoid photonic absorption and scattering over the pocket wall

Baggio WANG FAN

-----------------------------------------------------------

SHENZHEN JAAPSON TECHNOLOGY CO LTD

Building 2, Tongfuyu Industrial Park,Shenzhen, China, 518104

Tel: 86-755-82596922

Fax:86-755-82596922/82596923

skype: baggiowang0214

baggio.wang@funsunpcb.com

baggio@jaapson-pcb.com

www.jaapsonpcb.com

-----------------------------------------------------------

SHENZHEN JAAPSON TECHNOLOGY CO LTD

Building 2, Tongfuyu Industrial Park,Shenzhen, China, 518104

Tel: 86-755-82596922

Fax:86-755-82596922/82596923

skype: baggiowang0214

baggio.wang@funsunpcb.com

baggio@jaapson-pcb.com

www.jaapsonpcb.com

JAAPSON, The Expert in HDI Multi-layer PCBs

没有评论:

发表评论