With

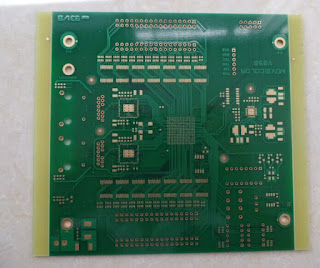

simple depth-milling a standard printed circuit board can be prepared for

flexible installations. So called "semi-flexible" printed circuits

are offering a cost-efficient solution. They save connectors and increase

reliability while decreasing size of the application and time needed for

assembly. Semi-flexible PCBs are the perfect solution if you have

flex-to-install requirements only and there is no dynamic bending during

operation.

Often layout designers are reluctant to upgrade from a

standard PCB with connectors to a notoriously expensive rigid-flexible printed

circuit. The advantages are immense, but so are the costs and the layout

requirements compared to standard PCBs. Many times this "jump" from

standard technology to a high-tech segment is not necessary. Many printed

circuits do not require dynamic bending capabilities in operation but only need

to be fit into the housing neatly. This is called a "flex-to-install"

requirement and here semi-flex offers a really cost-saving alternative

technology.

Production of a semi-flexible PCB is identical with the

manufacturing process of standard printed circuits. Semi-flexilbe boards can be

produced as single-layer, double-layer or multilayer PCBs. With the exemption

of a special solder mask that sustains bending, the materials are also

identical to standard printed circuits. The only difference happens at the end

of the production process when dedicated bending areas are milled down by

z-axis routing. The remaining material can be bend and is thin enough to only

carry the copper traces and little base material.

Design and installation of semi-flexible PCBs require

some attention and modifications:

1.

The PCB should only be bend with copper

on the outside of the bending area.

2.

Open copper structures, pads, annular

rings or vias in the rigid part of the PCB should have a distance of at least 1mm from the bending area. In special

cases 0,8mm are okay, too. The

semi-flexible are cannot contain any vias, drills or open copper structures.

The transition area from flexible to rigid should have a radius of 5mm or an obstuse angle.

Trace-to-outline distance in the semi-flexible area should be minimum 0,30mm .

3.

The maximum bending radius depends on

the lenght of the semi-flexible area:

4.

Currently, semi-flexible PCBs are possible

up to 8 layers, while only one outer layer can be "semi-flexible" per

bending area.

Baggio WANG FAN

-----------------------------------------------------------

SHENZHEN JAAPSON TECHNOLOGY CO LTD

Building 2, Tongfuyu Industrial Park,Shenzhen, China, 518104

Tel: 86-755-82596922

Fax:86-755-82596922/82596923

skype: baggiowang0214

baggio.wang@funsunpcb.com

baggio@jaapson-pcb.com

www.jaapsonpcb.com

JAAPSON, The Expert in HDI Multi-layer PCBs